Laser cutting

At Furhoffs, we offer advanced and energy-efficient laser cutting, where the material is processed and cut with high precision. Our laser cutting machines have a cutting capacity of up to 25 mm stainless steel and combine powerful performance with low energy consumption.

To optimize production, our machines are connected to an automated sheet metal storage system, ensuring an efficient material flow.

Edge Breaking

At Furhoffs, we offer precise edge breaking to eliminate sharp edges and laser spatter, resulting in safe and smooth final products. To meet different product requirements, we use two types of edge-breaking processes, tailored for various sizes and materials:

- Deburring Machine with Dry Grinding – efficient for fast and precise processing of sharp edges.

- Tumbling Machine – ideal for smaller products that require a gentle surface treatment.

Our processes guarantee high quality and safety in every detail, regardless of the size or shape of your stainless steel components.

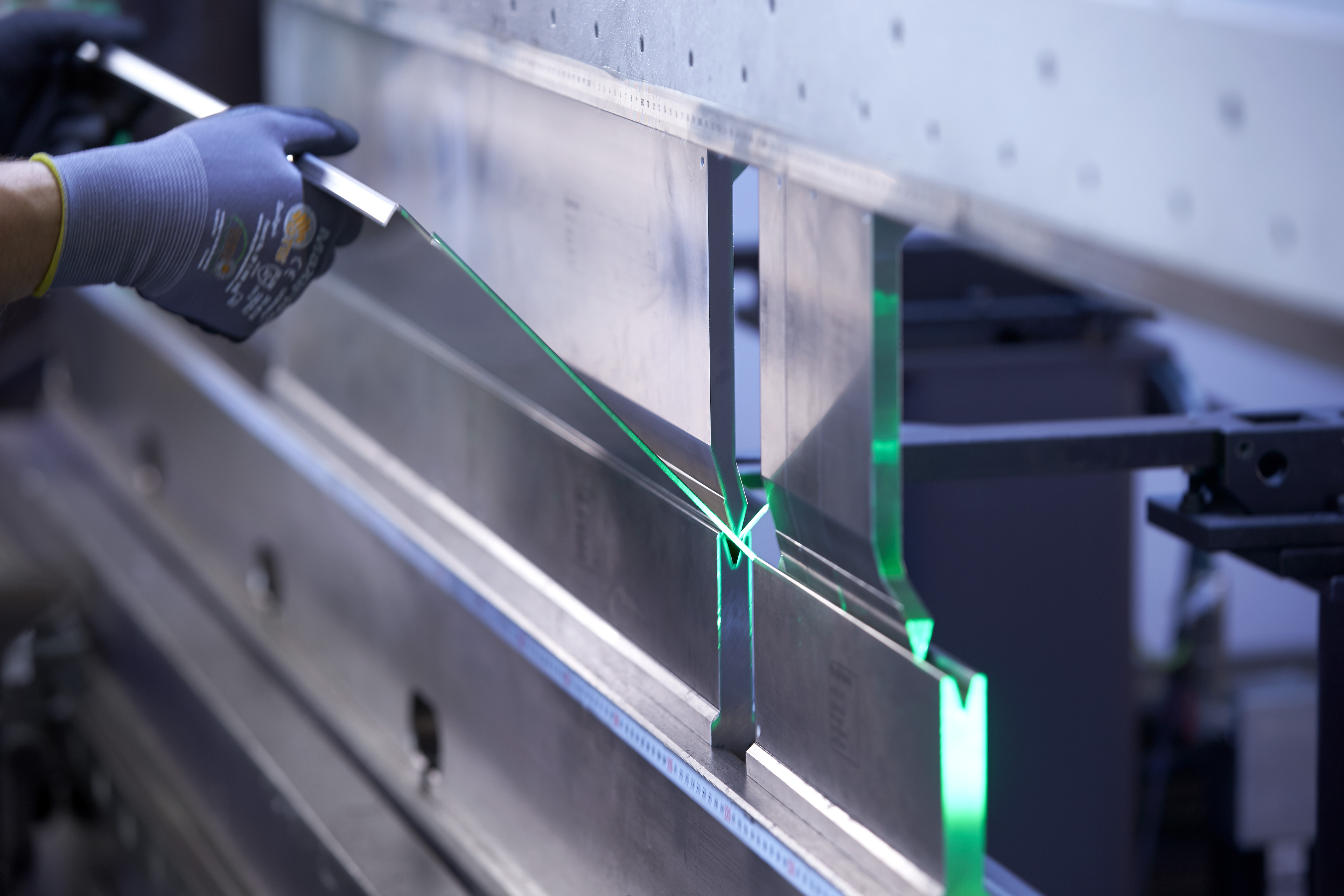

Forming

At Furhoffs, we offer a range of forming processes to give your products the exact shape you require. We have the capacity for the following forming techniques:

- Press Brake Forming – up to four meters, with both on- and offline programming for maximum flexibility and precision.

- Mandrel Forming

- Roll Forming

- Production Cell for Round Products – equipped with automated rolling machines, automated length welding, and end-forming machines for inward and outward flaring, ensuring efficient and accurate production of round components.

With our extensive forming capabilities, we can ta

Welding

At Furhoffs, we offer expertise in welding with both TIG and MAG, supported by a number of welding certifications that guarantee quality and safety. We have invested in advanced technology to ensure an efficient and precise welding process:

- Robot Cell for MAG-/CMT-Welding – optimizes the production flow and ensures high precision.

- Collaborative Robot for TIG Welding – enables flexible and safe welding, improving productivity.

- Spot Welders, Seam Welders, and Capacitor Discharge Welders for Bolt Welding – for various applications and material types.

We are certified according to the welding quality system ISO 3834-2, which confirms our commitment to delivering welded components of the highest quality.

Machining

At Furhoffs, we offer high-quality machining using modern CNC machines, as well as through our turning, milling, and drilling machines. The resources in our cutting department allow for precise machining of stainless steel components, ensuring that each product meets the strictest quality standards.

By utilizing advanced technology, we can perform complex turning and milling operations, as well as precision drilling, providing you with flexible and customized solutions.

We deliver meticulously machined stainless components with quality in every detail.

Surface Treatment

To ensure that the stainless steel surface retains its corrosion resistance after welding, Furhoffs offers comprehensive surface treatment services. A major advantage for our customers is that we have our own pickling facility with the capacity for dipping of products up to 3x2x2 meters.

We also offer a range of other surface treatment methods, including:

- Brush Pickling – for careful and precise work on detailed surfaces.

- Glass Bead Blasting – providing a smooth and fine surface, enhancing both appearance and durability.

- Manual and Mechanical Grinding and Polishing – to achieve the desired surface and finish on your products.

Marking and Inspection

At Furhoffs, we prioritize quality and precision throughout the entire production process. We offer advanced marking and inspection methods to ensure that each component meets your specifications and industry standards.

Our resources include:

- Laser Engraving Machine – for precise and durable marking of products, ensuring traceability and identification.

- Measuring Machine – enabling accurate measurements of component dimensions and tolerances to guarantee quality.

- Material Analyzer – for quick and non-destructive material identification, ensuring that the correct material is used in each product.

Through our marking and inspection measures, you can be confident that your stainless steel components meet the highest quality standards.

Assembly

Before a product leaves Furhoffs, we ensure that it is fully or partially assembled with the details and components we have manufactured. Our assembly service means that we do not just deliver individual stainless steel components but also help create complete solutions for our customers.

We offer:

- Packaging and distribution of smaller components and additional parts to simplify logistics.

- Marking and documentation according to your specifications, making it easier to trace and identify the products.

By choosing Furhoffs as your partner, we simplify your production process and ensure that you receive complete, high-quality products that are ready for use.